If you operate an air compressor, you're likely aware of the crucial role that proper air treatment plays. But what equipment is necessary for effective air treatment, and how do these devices function within the air treatment process? This guide will provide you with all the answers you need.

Why Compressed Air Treatment Matters

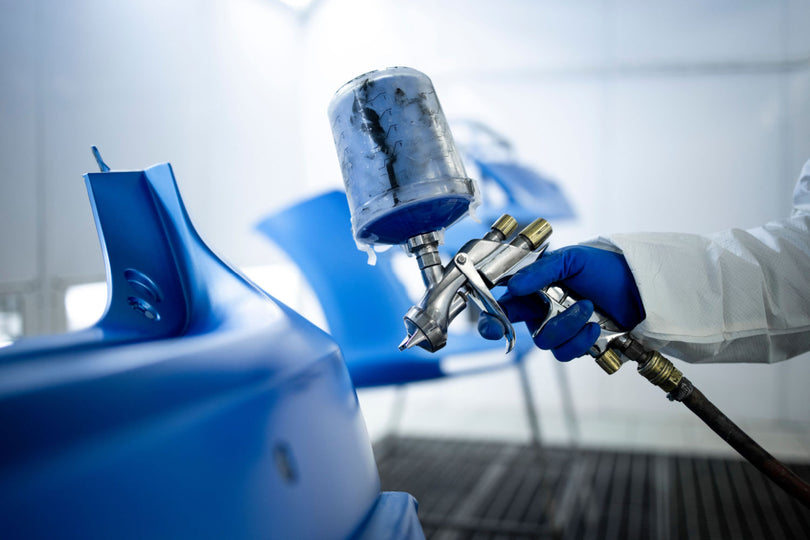

Compressed air treatment is a vital step that occurs after the compression process. Its purpose is to purify compressed air by eliminating contaminants, ensuring it is safe for various applications.

The level of air quality required varies depending on the industry. For example, medical-grade air compressors must produce compressed air of exceptional quality, whereas industrial compressors have different requirements.

The Compressed Air Treatment Process

Although the methods involved in air treatment may vary, the core process remains consistent:

-

Air Compression: Atmospheric air is drawn into the air compressor and compressed.

-

Contaminant Condensation: During compression, environmental impurities such as moisture and dust particles condense with the air. These impurities are detrimental to both the compressed air's intended use and the air compressor itself, necessitating their removal.

-

Moisture Removal: The compressed air is then passed through one or more types of air dryers to extract moisture. Air dryers can also follow air filters instead of preceding them in some setups.

-

Contaminant Disposal: The moisture and particulates separated from the air are safely drained and processed, often with the assistance of an oil-water separator. Any unused compressed air is stored in an air receiver, commonly known as a compressed air tank.

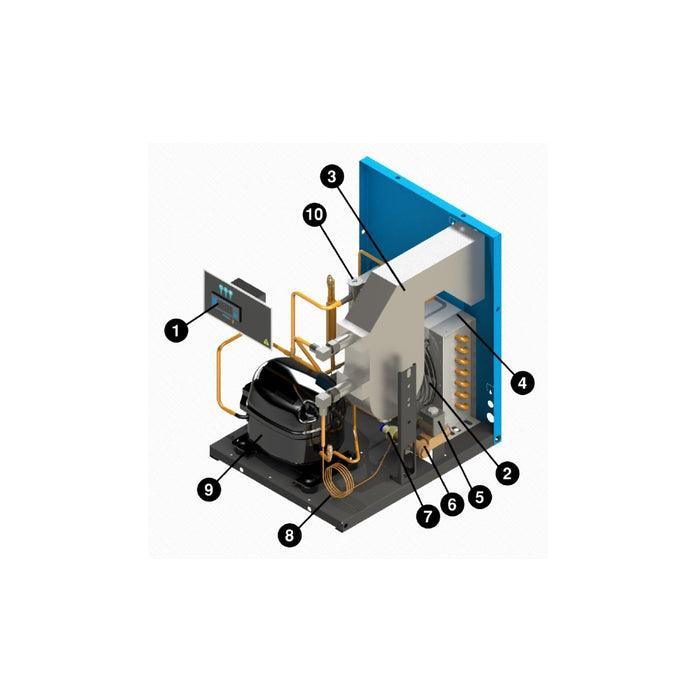

Essential Devices for Compressed Air Treatment

The effective treatment of compressed air involves the coordination of several devices to ensure a high-quality output. Here are the key components:

1. Air Dryers: Air dryers are responsible for extracting moisture from compressed air after the compression process.

2. Air Filters (Line Filters): These devices filter out particles, aerosols, and other impurities from the compressed air after compression.

3. Oil-Water Separators: These separators effectively separate water from oil for proper drainage.

4. Air Receivers: Air receivers enable the storage of compressed air for later use, commonly referred to as a compressed air tank.

5. Aftercoolers: Aftercoolers play a crucial role in cooling the compressed air after compression. Initially, compressed air is hot, making it unsuitable for immediate use. The high temperature can have adverse effects on equipment, particularly regarding lubrication.

Air Dryers vs. Air Filters

While both air dryers and air filters are vital for ensuring top-quality compressed air, they differ in their purification methods:

-

Air Dryers: These devices remove water from compressed air using various techniques, depending on the specific dryer type employed.

-

Air Filters: In contrast, air filters focus on eliminating particulate matter and aerosols from the compressed air. Notably, these aerosols can consist of both water and oil, not just water as in the case of air dryers.

Air Filter vs. Line Filter

Air filter, line filter, and air line filter all refer to the same compressed air device. You can use any of these terms when searching for information or replacement parts.

Air Dryer vs. Moisture Separator

Although the terms "air dryer" and "moisture separator" might seem interchangeable, these systems serve distinct purposes:

-

Air Dryers: As previously explained, air dryers extract moisture from compressed air to prepare it for use and protect your equipment from corrosion.

-

Moisture Separators: In contrast, moisture separators are employed to drain moisture from your air compressor post-filtration. They specialize in separating extracted water from extracted oil for safe disposal, earning them the alternative name of oil-water separators.