Compressed air quality assessment is crucial to ensure the efficiency and safety of industrial plants and applications that depend on this vital resource. Fortunately, several technologies and tools have emerged in recent years that greatly simplify this process.

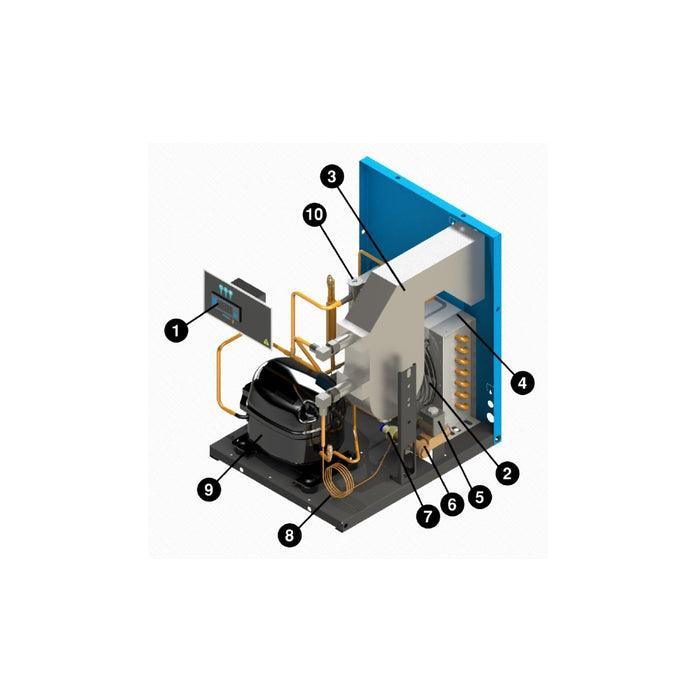

Humidity Measurement:

To monitor the humidity in compressed air, there are several options:

- Humidity Indicators: These are low-cost devices that provide a visual indication of the humidity level. However, they do not offer an accurate measurement.

- Chilled Mirror Technology: This technology offers higher accuracy, but requires frequent maintenance and periodic calibration.

- Capacitive Type Dew Point Sensors: Ideal for continuous monitoring, these sensors provide feedback to dryers, allowing for more accurate control and energy savings.

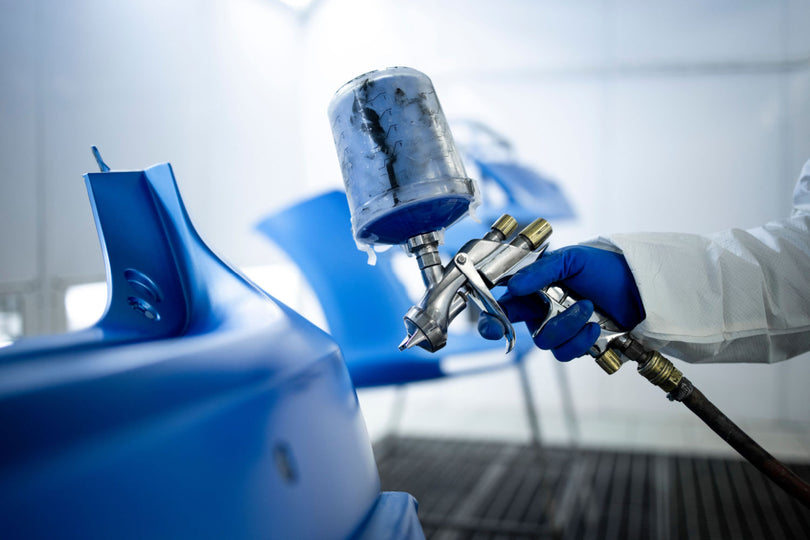

Oil Measurement:

To measure the oil content of compressed air, several solutions are available:

- Sampling Solutions: Like the O-box system, they offer quick and inexpensive assessment of the presence of oil.

- Glass Test Tubes: Used with a QDT filter, they allow measurement of low oil vapor concentrations up to Class 1 of ISO 8573-1.

- Photoionization Detectors (PID Sensors): They offer continuous monitoring with data storage, although some brands may give false results if moisture is recognized as oil.

- Gas Chromatography: This technology is the only method that can ensure compliance with even the most stringent air quality requirements.

Particle Measurement:

To measure particles in compressed air, laser technology is a reliable tool. However, getting the right sample is essential to ensure accurate results, especially when extremely high air quality is required.

In conclusion, the choice of instruments and techniques for compressed air quality control depends on the specific needs of the application and regulatory requirements. Adoption of advanced technologies and proper maintenance of instruments are critical to ensure a safe working environment and compliance with air quality standards.